Introduction

The objective for project 1 is

to create a Building Information Model (BIM) and Parametric Design for a

selected building of our choice. We are to choose a building that will

encompass all of the parametric modeling skills that we have acquired thus far.

The parametric modeling of the building was first started by collecting as much

information, such as drawings, plans, elevations, etc. on the building as was

possible. Once the information was gathered, a parametric, conceptual mass of

the building was created. This mass was parametrically controlled so that the

geometry of the building could be easily altered. Next, a parametrically

controlled envelop family was created and loaded into the building conceptual

mass family. Once the parametric mass model was created, a detailed BIM model

of the building was created that included: walls, floors, ceilings, windows,

and floor plans with accompanying furniture. Finally, realistic renderings of

the interior and exterior of the building were created along with various

screenshots that displayed how the building model could be parametrically

altered.

Proposed Building

Model

The

building I chose to model for the project was the Taipei 101 Tower located in

Taiwan. The Taipei 101 Tower can be seen in Figures 1 and 2 below. Construction

of Taipei 101 began in 1999 and was completed in 2004. It is currently the

world’s fourth tallest building in the following categories: structurally, roof

height, highest occupied floor. The spire reaches a height of 1,667 feet while

the roof and the top floor reach heights of 1,470 feet and 1,457 feet,

respectively. The tower also includes five basement floors which extend 103

feet below ground level.

|

Figure 1: Taipei 101 at Dusk

(Taipei Financial Center Corp. 2009)

|

Figure 2:

Exterior Facade

(Sekavic 2005)

|

Taipei 101

has multiple uses, but is mainly an office building. It houses retail

facilities on floors 1 – 4, a fitness center on floors 5 and 6, offices on

floors 7 – 84, restaurants on floors 86 – 88, observation decks on floors 89,

91, and 101, and communication facilities on floors 92 – 100. Beneath the

building is a station for the Taipei Mass Rapid Transit (MRT) awaiting the

construction of the Hsinyi line. The tower also includes the two fastest

elevators in the world installed by Toshiba and has a 900 ton tuned mass damper

on the 87th floor to counteract earthquakes and typhoons. (Skyscraper Source

Media Inc. 2012) The design and architecture of the building is heavily based

on the Chinese culture. The building protrudes from the ground like a bamboo

shoot and the eight inverted trapezoidal sections that make up the majority of

the tower use the Chinese pagoda as their form. The eight trapezoidal sections

also represent the lucky number eight which means blooming or success. Most

aspects of the design, layout and planning of the tower were consulted on by a

Feng Shui master. (Sekavic 2005) The façade of the tower is composed of

unitized glass wall and steel.

Parametric Design

Intent

As can be seen from the schematic

representation of Taipei 101 in Figure 3 below, the tower is essentially

constructed by stacking various “blocks” on top of each other. The two main

components of the tower are the base trapezoidal section and the eight inverted

trapezoidal sections above the base. The base component is wider at the base

than at the top, while the upper eight components are wider at the top than at

the base creating the sloping envelope as seen in the figure below. The eight

sections above the base also contain notches at each of the corners along the

height of the inverted trapezoidal section. In order to parametrically control

these components, they were created as individual conceptual masses with their

various widths and heights as the driving parameters. The notches in the eight upper sections are

dependent on the overall outer and inner widths at the top and bottom of these

sections and were also set as parameters. This will be described further in the

following section. Once these conceptual masses were created they were loaded

into a new total building family and essentially stacked on top of each other.

The components above the eight

inverted trapezoidal sections were all created in the same manner using similar

driving parameters since they all use the same basic trapezoidal form. For the

components that are circular in form, they were created using either a revolve

or sweep with driving parameters defined as radii and height. These were then

uploaded into the full building family and placed in their appropriate places.

The exterior façade of the building is composed of a rectangular curtain wall

system which was created as a curtain wall by pattern mass family. The height

and width of each window frame is controlled by the divide surface function in

Revit, while the width and thickness of the frames are parametrically driven

along with the materials for the frame and window pane. A separate curtain wall

family that used the same parameters as the one previously explained was also

created in order to easily change the color of the windows on the top edge of

the tower base component and the upper eight inverted trapezoidal components.

This is also described in further detail in the following section.

Parametric

Modeling

Building Mass

Model

The parametric mass model for

Taipei 101 is composed of 22 conceptual masses stacked and aligned on top of

one another. Of the 22 conceptual masses, there are 12 conceptual mass families

with different shapes and dimensions that were used to create the full tower.

Because most of these were created in the same manner, only a few of the main

parametric building families are described in detail for clarity. The building

families that make up the full tower family that are described can be seen in

Figures 4 through 7 below and include: tower base component (component 1), the

inverted and notched trapezoidal components that make up a majority of the

tower’s height (component 2), the smaller main tower on top of the eight

inverted trapezoidal sections (component 3), and the three trapezoidal sections

on top of the smaller main top tower (component 4).

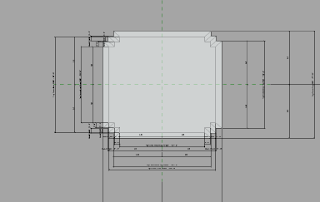

|

Figure 4: Component 1 Conceptual

Mass

|

Figure 5: Component 2

Conceptual Mass

|

|

Figure 6: Component 3

Conceptual Mass

|

Figure 7: Component 4

Conceptual Mass

|

Parametric Modeling of Component 1

To create component 1 of the

tower, the base of Taipei 101, the length and width of the base and the length

and width of the top were defined as separate type parameters. The height was

also defined as a type parameter. Once the length, width and height parameters

were set to their respected values, a solid extrusion of this component was

created. The driving parameters for this component are shown in Figure 8 below.

Figure 8: Component 1 Parameters

Parametric Modeling of Component 2

In order to create the parametric

mass for component 2, the top and bottom faces were drawn using model lines to

incorporate the notches in the corner edges. The top face of this component can

be seen in Figure 9 below.

Figure 9: Top Face of Component 2

Once the top and bottom faces

were drawn, the overall length and width of each face were defined as separate

type parameters for both the bottom and top face. As can be seen from Figure 9

above, each side of the faces have four notches that make a diagonal cut in

each of the four corners. In order to keep these notch lengths equal when the

length and width of this component is changed, a parametric formula was defined

for the notch width. The parametric formula for the notch width can be seen in

Figure 10 below. With the notch width parametrically defined, the dimensions of

the component can be changed while the notch lengths always remain equal to

each other. Once all of these parameters were defined a solid extrusion between

the top and bottom faces was created to create the form of component 2.

Figure 10: Component 2 Parameters

Parametric Modeling of Components 3 and 4

The parametric models of

components 3 and 4 were created in the same manner as the parametric model for

component 1. The base length and width, and the top length and width of each

component were set as type parameters. The height of each component was also

set as a type parameter. After these parameters were defined, again, a solid

extrusion was used to create components 3 and 4. Figures 11 and 12 below show

the parameters defining component 3 and 4.

Figure 11: Component 3 Parameters

Figure 12: Component 4 Parameters

As was previously mentioned, the

remaining conceptual mass families were created in a similar manner to the ones

just described. After all of the individual building components were created,

they were all loaded into one single building family and stacked on top of each

other. The families in which multiple components made up the full building were

replicated the required number of times and placed in their respected

positions. The total building conceptual mass family is shown in Figure 13

below.

Figure 13: Full Building Conceptual Mass Family

Façade Modeling

The façade of Taipei 101 is

composed of a rectangular curtain wall system made up of steel frames and glass

window panes. The parametric mass model of the curtain wall was created by

using a curtain wall by pattern. The exterior window frame was created by using

a rectangle with the sweep function to make the form of the frame around the

entire rectangular window frame. The thickness and width of the frame element

were assigned as parameters so that the frame and overall curtain wall

appearance can be easily changed. The color and transparency of the glass along

with the frame material was also assigned material parameters so that their

colors can be changed quickly. Figure 14

below displays the parametric conceptual curtain wall mass.

Figure 14: Parametric Curtain Wall Conceptual Mass

Once the conceptual mass of the

curtain wall system was completed, the divide surface tool was used in the main

building family so that the curtain wall system could be applied to the façade

of the building. The number of rows and columns for the curtain wall grid was

manually adjusted to make the building look as close as possible to the real

one. The gold panels at the top of each component are a separate curtain wall

conceptual mass that was created the same way as the main curtain wall system.

This was done so that these panels could be assigned different materials and

colors without changing the overall curtain wall pattern. Figure 15 displays

what the curtain wall system looks like in the building mass family.

Figure 15: Curtain Wall System

Screen Shots of Parametric Families

Screen Shot 1

This screen shot was taken after the width and height parameters of

the component of the tower were changed. The bottom width was made smaller,

while the top width and height were made larger.

|

Screen Shot 2

This screen shot was taken after the width and height parameters of

the mass family used to create the eight inverted trapezoidal sections were

changed. The height and top width of this component were both drastically

increased.

|

Screen Shot 3

This screen shot was obtained by changing the parameters of the

components that make up the top spire portion of the tower. These were also

height and width parameters. The components whose parameters were changed are

the ones that look out of proportion to the rest of the building.

|

Screen Shot 4

This last screen shot was taken after the width and thickness

parameters of the curtain wall system frame were changed. The frame width was

dramatically increased. The color and material of the glass panes and the

frame can also be changed, but were not for this screen shot.

|

Interior Modeling

Because the building very large

and contains so many floor levels, a typical office floor plan was created. All

of the exterior rooms are offices and conference rooms while most of the rest

of the usable space is composed of work stations. The interior core of the

building contains restrooms, elevators and stairs. These spaces are labeled,

but no components were added due to time constraints. The typical office floor

plan layout is shown in Figure 16 below.

Figure 16: Typical Office Floor Plan

Renderings

The figures below show the exterior and interior floor that

was modeled of Taipei 101 in realistic renderings during the day.

Figure 17: Total Tower Exterior Rendering

Figure 18: Tower Top Exterior Rendering

Figure 2: Typical Office Floor Interior Rendering

Revit Modeling Issues/Comments

The main issue encountered when developing

this model was creating a single curtain wall conceptual mass that would allow

me to change the color and material of individual panels. I experienced this

problem when I tried to change the color and material of the panels at the top

of each building mass. I resolved this issue by creating a new curtain wall

conceptual mass with different materials and colors. I then selected the

individual panels that I wanted to change and changed the curtain panel type to

the one I wanted. Although this is probably not the most sophisticated way to

resolve the problem, the results were satisfactory and I believe that

parametrically changing these panels is beyond the scope of this project.

However, after methods for Revit programming is learned in the future, this

problem will probably be able to be solved much more easily and quicker. I also

had a few constraint issues when flexing the parameters of my building family,

but they were easily resolved by locking and unlocking some of the alignments I

created.

Works Cited

Taipei Financial Center

Corp. (2009). “Taipei 101,” <http://www.taipei-101.com.tw/en/Tower/index_tower.asp>

(Feb. 23, 2012).

Sekavic, Daniel. (2005). “Taipei 101-Taipei Financial Center,” <http://www.daapspace.daap.uc.edu/~larsongr/Larsonline/SkyCaseStu_files/Taipei101.pdf>

(Feb. 23, 2012).

No comments:

Post a Comment